CDC Collaborated Product Design | US Patent Protected

Due to intermittent power outages in global laboratories , the lack of continuous vortexing can result in insufficient mixing, potentially leading to test failures. Furthermore, the absence of battery backup in smaller devices, which are used for short periods, underscores the critical necessity for the development of manual Vortex (solution mixing device) as a key design goal.

About.

This project is a collaboration between the CDC and Georgia Tech, guided by Prof. Wendell Wilson.

I took the lead in the product design phase, developing the internal mechanism, managing resource procurement, crafting the product's aesthetics, and collaborating with another colleague on design research and mounting design.

Introduce Gear Tex

The Gear Tex is the only manually operated laboratory mixer on the market. It fits tubes of various sizes, ensuring homogenized solutions comparable to those achieved with electrical vortex equipment. It also allows transitions between vortex mixing and centrifugation (solution separation) functions by changing different mountings.

Gear Tex achieves a spinning speed of up to

880 RPM

This performance rivals that of electric machines, which range from 10 to 60 seconds, varying by solution type and specific needs.

Mixing or separating solutions within

15-60 sec

Unlike traditional vortex machines that require manual holding of tubes, leading to hand fatigue from vibration, irregular tube caps, and prolonged holding, Gear Tex eliminates the need to manually stabilize tubes against vibrations, markedly reducing researchers' exertion.

Gear Tex is a 2 in 1 machine that enables easily transitions between a vortex mixer and centrifuge with a simple swap of mountings, enhancing its versatility across various scenarios.

Mountings

Polypropylene

Silicone Attachments

Suction cups

Neoprene

Cover

Polypropylene

Pump

Polypropylene

Silicone Coated

Safety guard

AR Acrylic

Polypropylene

Silicone Coated

Gear Tex features an innovative inner gearbox design that not only guarantees its functionality but also ensures a durability surpassing that of conventional electrical machines, making it a reliable choice for international laboratory needs.

Gear Tex Commitment

Gear Tex stands out as the sole manually powered vortex machine, offering an ideal solution to mixing challenges faced by international laboratories during intermittent power outages.

Power Outage Solution

_e.jpg)

Gear Tex eliminates the need for users to manually hold tubes during the mixing process, addressing researchers' concerns about hand fatigue effectively.

Reduce Researcher's Exertion

The easy transition between vortex and centrifuge modes enhances its versatility.

2 in 1 Machine

Gear Tex's meticulously designed gearbox that mirrors the durability and robustness of a mechanical watch, promising longevity. Additionally, its materials are resistant to chemicals, ensuring resilience in various laboratory environments.

Reliable and Durable

The Gear Tex machine costs $250–$350, with potential savings through bulk gear purchases or cheaper suppliers. Compared to the $550–$3000 range of electrical vortex machines and 2-in-1 devices, Gear Tex provides a cost-effective laboratory alternative.

Economical Lab Equipment

Gear Tex's design and thoughtful CMF choices distinguish it from typical lab equipment, addressing researchers' feedback on the dull appearance of standard tools by adding visual appeal to functionality.

Aesthetic Design

Research

Field Study & Semi-Structure Interview

By observing and interviewing researchers at Georgia Tech's Biology, Biotechnology, and Biochemistry Labs on their use of vortex machines, gathered insights into their needs and frustrations. Analysis of this data, alongside a task analysis of the existing equipment, led to the summarization of design requirements.

Task analysis

Design requirements

Must-have features

Fast mixing

- Rapid mixing is crucial for lab tasks. (<1 min)

Homogenization

- The mixing quality should be equivalent to current machines.

Nice-to-have features

Stable + fixed

- Incorporates a stabilization system to minimize vibration transfer and prevent bouncing.

One hand operation

- Allow for one-handed operation to simplify use and reduce effort.

Independent from electricity

Convertible

- Entirely manually powered equipment designed to circumvent problems associated with power outage.

- Convertible between vortex machine and centrifuge to enable different using scenarios.

No contact with fluid

- Eliminates direct contact between stirring devices and the fluid during mixing.

Aesthetic pleasing

- Consider aesthetics in design to enhance the user experience and enjoyment.

Reduce fatigue

- Minimizes the risk of injuries and fatigue resulting from extended periods of mixing and vibration.

Market analysis

The absence of non-electric vortex machines in the current market reveals significant untapped potential in this niche.

Current market for existing electric lab vortex machines, prices range from $500 to $3500. For 2-in-1 machines (vortex + centrifuge), the price spectrum spans from $1500 to $4500. Based on this, Gear Tex target selling price was set between $300 to $700.

Ideation

Explorations

Explore the possible design critiria, adopting variable design methods and test the potential design approaches, then validate the final design decision.

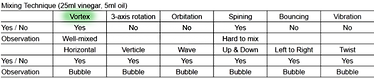

Morphological Matrix + Test

Utilizing a morphological matrix and insights from research, feedback, and test, a clear direction emerged: a mechanical system for generating the necessary spinning motion in a vortex shape. Three key power technologies— weight (pressure, body weight...), hand cranking, and rope pulling —were identified. For stable use, the design includes a suction cup to secure the device to bench-tops.

Sketches

Option 1 involves generating spinning motion by pulling a rolled-up rope.

Option 2 utilizes cranking to activate gears for spinning.

Option 3 emerged as the favored choice among researchers due to its stability on the benchtop, one-handed operation capability, and seamless conversion between vortex machine and centrifuge functionalities—ideal for international lab environments. Furthermore, the pressing motion was found to be less strenuous compared to the other options, which necessitate larger movements, potentially disturbing nearby researchers and transmitting more vibration to the desk.

Option 3 employs a push mechanism to engage gears for spinning.

Prototype

First Iteration

The initial prototype utilized 3D-printed gears to assess the feasibility of fully 3D-printing the device. Challenges encountered included excessive friction, inability to achieve desired speeds, and halted rotation due to pump recoil. The focus for the subsequent model is on enhancing speed and maintaining continuous rotation.

The second iteration incorporated a metal gear-set, enabling Gear Tex to reach speeds of up to 880 RPM for mixing and separating solutions within a minute, and maintaining rotation after the pump is released. This model also features the ability to switch between vortex and centrifuge functions. CDC researchers have validated its utility and functionality, with plans for further testing in international labs.

Second Iteration

Vortex Mode

Centrifuge Mode

Video Demo

--- back to top ---